Synchronous Drive Specifications

SCOPE.

This standard applies to those belts and pulleys intended for mechanical power transmission, and where positive indexing or synchronous type service may be required. These specifications cover three standard belt sections which are established on the basis of belt pitch. These sections are designated MXL (0.080 inch pitch), XL (0.200 inch pitch), and L (0.375 inch pitch). It also covers dimensions for two double sided sections: DXL (0.200 inch pitch), and DL (0.375 inch pitch). Dimensions of synchronous belts and pulleys together with basic design data are covered in this standard. Dimensions in customary English units are provided. This standard does not apply to automotive drives for which other standards exist. SYNCHRONOUS BELT PULLEYS

DIAMETERS.

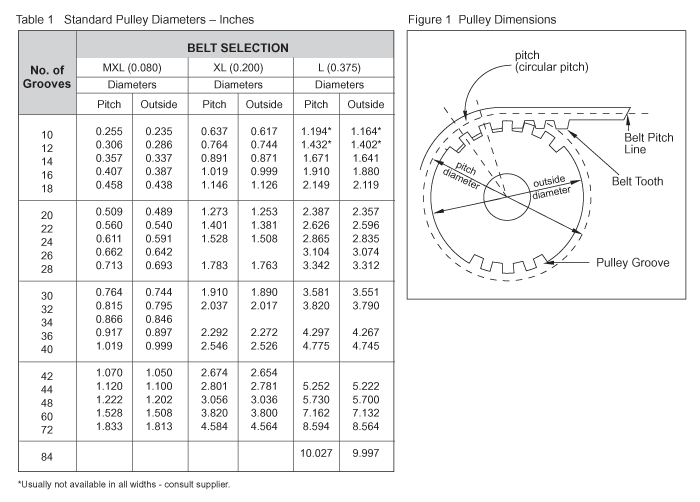

Table 1 lists the standard pulley diameters by belt section (pitch). Figure 1 defines the pitch, pitch diameter, outside diameter, and the pitch line differential.

WIDTHS.

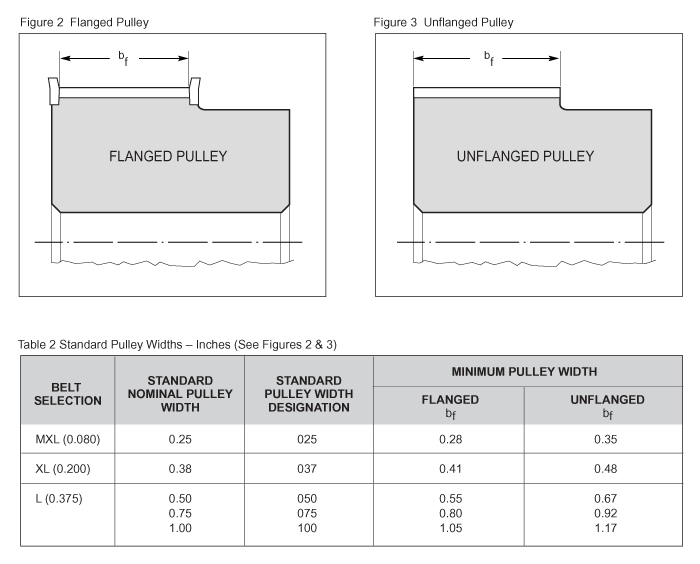

The standard pulley widths are shown in Table 2 for each belt section. The nominal pulley width is specified in terms of the maximum standard belt width the pulley will accommodate. For example, only one standard nominal width is specified for the XL Belt Section – 0.38 inches. This pulley width can be used for the standard XL belt widths of 0.25 and 0.38 inches. The actual minimum pulley width, whether flanged or unflanged, is also specified in Table 2 and shown in Figures 2 and 3.

SIZE DESIGNATION.

Pulleys are designated by the number of grooves, the belt section, and a number representing 100 times the nominal width. For example, a 30 groove L section pulley with a nominal width of 0.75 inches would be designated by the number 30L075.

GROOVE PROFILE.

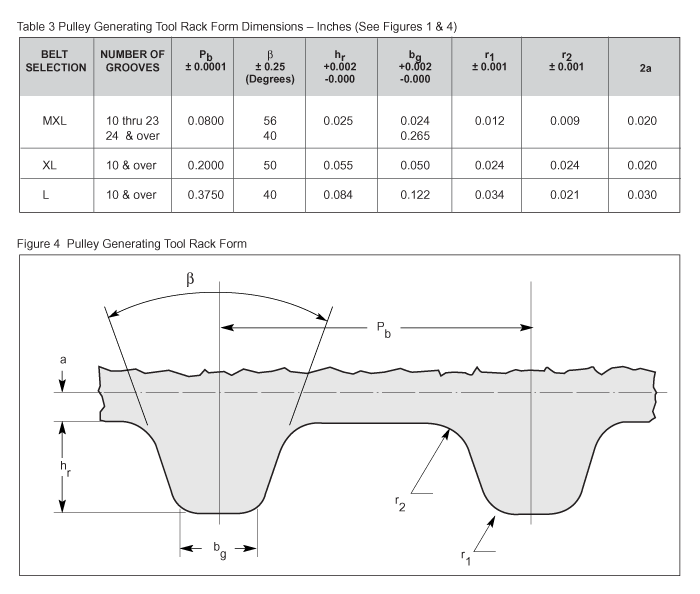

The groove profile is defined as the profile formed by the generating tool rack form described in Table 3 and Figure 4. The sides of the grooves shall be free of surface defects, and the edges of all grooves shall be rounded. The flanks of the grooves shall have a finish of 125 microinches, or better.

FLANGE DIMENSIONS.

The details of suggested pulley flange design are shown in Table 4 and Figure 5.

KEYSEATS.

Keyseats in the hubs of pulleys are shown in Figure 6 and shall conform to the dimensions and tolerances given in Table 5. BORE

TOLERANCES.

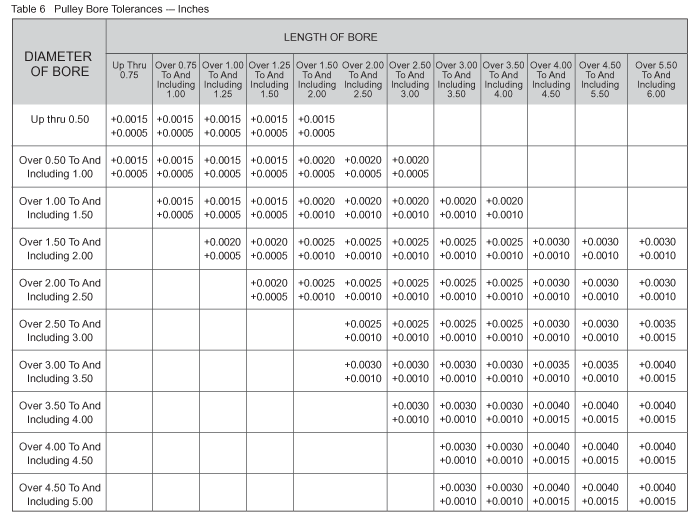

Table 6 gives the bore tolerances for belt pulleys.

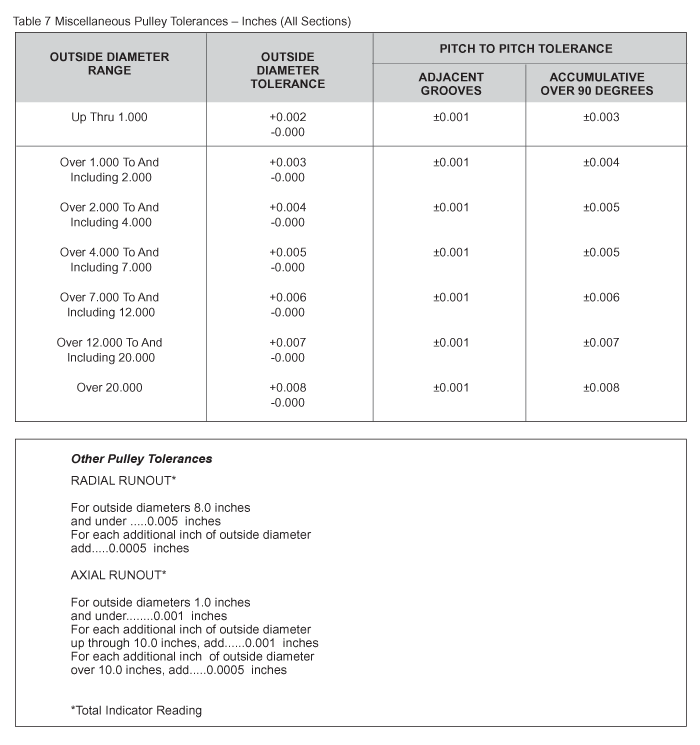

MISCELLANEOUS TOLERANCES.

Table 7 includes the following miscellaneous pulley tolerances: Outside Diameter, Radial Runout, Axial Runout, Pitch Accuracy